All Categories

Featured

Table of Contents

- – Furnace Installation Burbank, CA

- – Instant Air Solutions

- – Commercial Air Conditioning Service Burbank, CA

- – Commercial Hvac Burbank, CA

- – Furnace Services Burbank, CA

- – Heating Contractor Burbank, CA

- – Commercial Hvac Service Near Me Burbank, CA

- – Ductwork Cleaning Burbank, CA

- – Air Conditioning And Heating Company Burbank...

- – Ductwork Cleaning Burbank, CA

- – Commercial Hvac Installation Burbank, CA

- – Commercial Air Conditioning Service Burbank, CA

- – Commercial Air Conditioning Service Burbank, CA

- – Commercial Hvac Burbank, CA

- – Commercial Air Conditioning Service Burbank, CA

- – Instant Air Solutions

Furnace Installation Burbank, CA

Don't think twice to contact us for more details or a customized quote on commercial cooling and heating systems (Furnace Installation Burbank). Whether you curious about a or a for your business, we're below for you

Here are four vital decision variables that will certainly define the HVAC-BAS execution you wind up accomplishing. Allow's be actual: a/c control and automation are a significant part of your bachelor's degree's reason for existing. In an ideal world, you would certainly mount an all-new enhanced bachelor's degree with every new cooling and heating installment. However, unless you're lucky (or abundant) sufficient to be able to build from scratch, you're extra likely to be dealing with some type of legacy implementation.

Technical fixes aside, the size of your building and what it is made use of for do matter a great deal. Your integration job will certainly scale straight with flooring space served since any kind of solitary pump, blower, or trainer will only have the ability to serve a collection number of square feet. The complexity of your system can likewise include material and labor expenses due to the fact that the variety of assimilation obstacles that require to be fixed will raise, even if the individual repair is technically quite simple.

Commercial Air Conditioning Service Burbank, CA

Pick the Right Modern Technology and Partner Select a partner with broad industry direct exposure and the capability to deal with little projects as well as present massive executions. Search for experience with the most recent IP-based methods as well as a knack for integrating heritage proprietary systems with more recent technology - Furnace Installation Burbank. Take into consideration the value of full-service professionals who can assist you from preparing to setup of your integration and assist with follow-up services

Setting up software application for smooth communication between systems. Updating the existing Bachelor's degree graphical user interface to enable HVAC procedures to be checked, managed, and automated. Evaluating and Optimization Comprehensive testing to make sure the integrated system operates correctly.

Commercial Hvac Burbank, CA

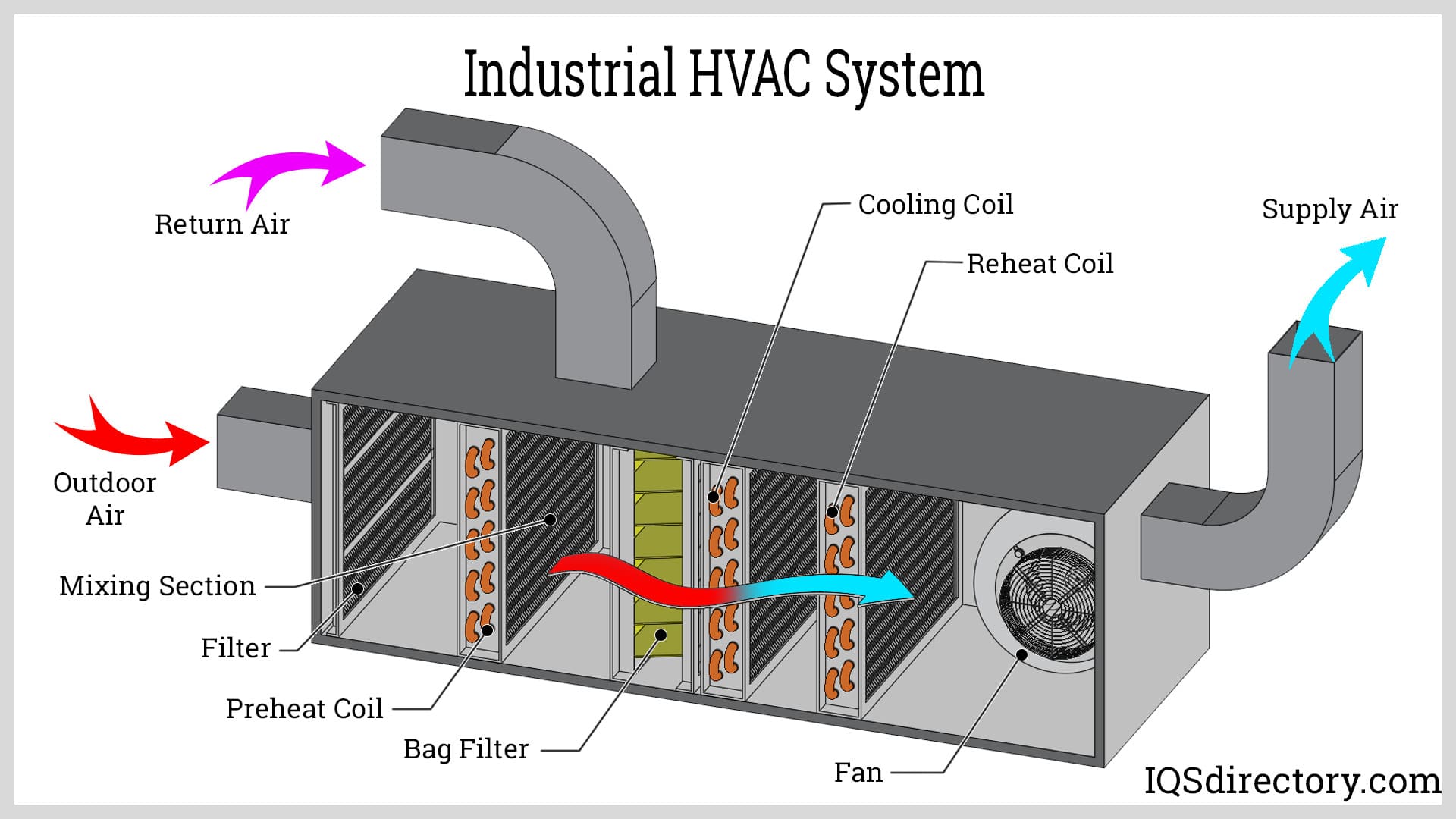

Industrial heating and cooling systems comprise a number of crucial components that collaborate to preserve optimum air problems:1. these units flow and problem air throughout the structure. 2.: in charge of cooling down the air in bigger industrial spaces. 3.: give heating for the building when required. 4.: disperses conditioned air throughout the center.

Straight digital controls (DDC) play an important duty in optimizing both IAQ and power performance. These systems allow for accurate surveillance and adjustment of HVAC operations based on real-time data.

Discover our considerable selection of energy-efficient cooling and heating equipment and regulates designed to boost air conditions and decrease power consumption. From sophisticated heating and cooling systems to wise structure automation solutions, we offer the tools you need to develop a much healthier, much more reliable indoor atmosphere. Link with us today to find out even more!.

In this blog site, we'll evaluate a current task which needed the upgrade of an industrial a/c control system for a longtime customer. The center functions as a living, job, and worship facility for up to 137 individuals to sleep, consume, interact socially, function, and prayer. Throughout the day workers tend to various facility procedure tasks in addition to sort and distribute donations of home products and garments.

Furnace Services Burbank, CA

Five of these Air Handling Units were the Warm Deck/Cold Deck Multi-Zone Type. Great for their time, they gave remarkable comfort with both cold and hot air at the very same time which permits areas to both warm and amazing at the same time. Sadly, they're currently considered very inefficient since a typical system provides both 55-degree cooling air and 100-degree home heating air to every one of the zones.

Hot Deck/Cold Deck multi-zone systems became out of favor due to inadequacy and the 1970's oil dilemma. Pneumatically-driven Controls usage compressed air to control and operate actuators which open and close dampers and shutoffs throughout the cooling and heating system at varying pressure. The stress relies on the temperature level sensing units. For their time, pneumatically-driven controls carried out all right with modest precision.

Heating Contractor Burbank, CA

At Some Point, Estes Commercial's commitment and responsiveness convinced the organization to include all the buildings under their control. One January early morning greeted the homeowners without warm in the cooking area, dining hall, and social hall. The organization picked to update the controller for the failed Air Handling Device to a brand-new Honeywell Eagle-AX Controller.

Convenience returned once Estes mounted the brand-new Eagle-AX controller in the Kitchen, Dining Space, and Social Hall areas. In March another Air Handling Unit over some of the living quarters suddenly damaged down.

Commercial Hvac Service Near Me Burbank, CA

Within a week one more controller offering another air trainer began having problems. It came to be clear the Andover system was rapidly failing around the building. A whole system upgrade was needed but the funds were not immediately available. To maintain the center operational each stopped working controller was purposefully replaced one by one to maintain the building functional.

Changing all of the controls with brand-new innovation permitted the system to stay functional. In addition, it permitted Estes Commercial to implement more complex control schemes, such as linking all of the units together.

The even more traditional water temperature level setpoints allowed the chiller and central heating boiler to run even more power efficiently. Secondly, it allowed the water side economizer to operate more often during mild climate conditions. This more lowered energy usage. Very important to a nonprofit! Thanks to the brand-new controls, the main building plant and the Warm Deck/Cold Deck Air Handling Units run more power successfully.

Ductwork Cleaning Burbank, CA

This allowed extra reliable procedure of the Air Handling Units themselves along with minimized needs on the main plant. This allows it to also change to a lot more conservative setups when the areas fit. Estes Commercial made a decision the best way to control each team of devices was to incorporate them and make use of one controller.

With this controller, the two units work together off of one temperature level and one setpoint to comfort the space. Both devices also worked in a lead/lag plan with transition based upon unit runtime. This meant one unit was not constantly beginning very first or doing all of the work.

Air Conditioning And Heating Company Burbank, CA

This protects against one system from wearing before the various other. The not-for-profit company initially selected to change the controls system because of the rapid failings of the old and existing Andover Control System. The potential customers of far better system administration via an extra straightforward, graphic interface were the main consider the choice to change the system.

Keeping the facility functional was the crucial consider making our decision to update the business heating and cooling control system. What we discovered afterward was far better system control than ever and we were a lot much more comfortable. Power savings experienced from the system is a big plus," said the customer.

AI is spearheading advancements in HVAC control system programming, causing smarter, greener, cooler options. These intelligent systems utilize substantial amounts of data to make anticipating adjustments in environment control. Consequently, individuals delight in comfy living areas that are fine-tuned to their patterns and choices. AI's role in this improvement can not be overstated; it is the driving pressure behind considerable renovations.

As the system collects extra information, it discovers and fine-tunes its reactions. In doing so, it reduces manual inputs and takes full advantage of functional performance. These AI-driven systems might quickly be basic in modern homes and businesses. In addition, advancements in AI have brought about HVAC systems that anticipate and react to exterior problems.

Ductwork Cleaning Burbank, CA

This class in programs shows a stride toward freedom in structure climate administration. It's a growth that places less pressure on the grid and even more control in homeowners' hands. Fundamentally, the incorporation of AI in cooling and heating programs is a significant leap. It stands for a junction of technology and ecology, where both work towards common benefits.

HVAC controls are used to regulate the procedures of home heating and cooling systems. In most important structures, Heating, Ventilation, and Air Conditioning (HEATING AND COOLING) is used in all business, property, and commercial atmospheres. It is largely a control system with sensing devices that links an unbiased problem with an actual state like temperature level.

Commercial Hvac Installation Burbank, CA

With its head office in Munich and branch workplaces across the world, Siemens AG is a German international corporation service and the biggest commercial manufacturing venture in Europe. The firm's main divisions, which match to its core business procedures are sector, energy, healthcare (Siemens Healthineers), infrastructure, and cities. Cloud computing makes use of web servers situated in a remote area to aid with information storage space, process execution, and company operation.

Professionals preserve a range of data in advanced heating and cooling control systems, including info about a/c tons, constructing tools, proposals, maintenance tasks, and a lot more, which is produced in a number of different systems. Numerous sophisticated heating and cooling control systems companies are developing and releasing brand-new solutions. Technology-wise, these brand-new items are advanced than their earlier choice.

It's our goal to locate the most cost effective buildout without compromising top quality. We also pride ourselves as problem solvers. We do not come to our teammates with issues unless we have remedies to use.

Typically, a picking up gadget is used to contrast the actual state (e.g.

Then, after that control system draws a conclusion as to what action has to has actually taken (e.g. start the begin) HVAC systems are classified as categorized self-contained unit packages or plans central systems. Central controllers and the majority of terminal device controllers are programmable, suggesting the direct electronic control program code might be customized for the planned usage.

The system can be scheduled for occupancy or the configuration can be transformed from the BAS. In some cases the BAS is directly managing the cooling and heating elements.

Commercial Air Conditioning Service Burbank, CA

consisting of thermostats, condensers, and chillers, have actually transformed from straightforward dials and switches over to innovative devices that handles climate with accuracy. These, including innovative thermostats and computrols, are the minds behind the scenes, optimizing comfort and efficiency in imposing workplace blocks and stretching manufacturing facilities alike by controling refrigerators and condensers.

A regular A/c control system consists of a number of components working with each other, such as thermostats, condensers, computrols, and cooling agent. Sensors gauge air temperature level, top quality, and sometimes humidity.

Commercial Air Conditioning Service Burbank, CA

Controllers resemble the mind of the system. They choose based upon sensor info. Outcome gadgets then act upon these decisions. Thermostats and HVAC controllers can transform heating or air conditioning tools, such as refrigerators and service refrigeration systems, on or off within a cooling and heating controls system. Communication between these components takes place through a network.

Imagine a building that never sleeps. Lights and computers are off, but the A/c chillers are still running full tilt, disregarding the floorplan's energy-efficient style and disregarding the photo our items job of sustainability. Provider refrigerators' controls act as the practical chauffeur for the computer system, transforming products down when demand drops.

It causes disruptions and can be costly to repair. Controls offer a smarter way: anticipating upkeep. They keep an eye on just how each software application and computer product does day-to-day, regularly monitoring individual solution testimonials. Any type of indicator of computer problem, like uncommon resonances or temperature level spikes in the CLP system, triggers a solution sharp and an image alert.

Commercial Hvac Burbank, CA

Variable Regularity Drives (VFDs) optimize motor speeds in a Cooling and heating system's followers and pumps, enhancing the performance of these items. By integrating VFD software application, the solution life of the system prolongs while maintaining ideal performance.

This is what zoning controls use. Each zone or area within the United States carrier operates individually, many thanks to innovative software application products that take care of these common systems. In a domestic setting with a multi-floorplan, the rooms can be kept cooler at night utilizing our items, while usual areas stay warmer throughout the day through the reliable monitoring of the carrier system.

These variable control products adapt the interior temperature based on modifications outside, ensuring the typical carrier cooling and heating equipment operates efficiently in the US. Today's typical thermostat products feature straightforward interfaces developed for simplicity of use by the ordinary provider of the English language (en). With touch screens and user-friendly software, adjustments to our usual service provider products are straightforwardeven for those not tech-savvy.

Commercial Air Conditioning Service Burbank, CA

Products made as devices are necessary for understanding how energy is generally utilized in a structure, and the carrier of that energy. Our items give thorough info about when and where power is frequently consumed one of the most in the United States, assisting providers in optimizing their power use. With this information, services can determine common locations to boost efficiency in their product service provider procedures.

Instant Air Solutions

Address: 412 W Dryden St Apt 6 Glendale, CA 91202Phone: (747) 307-6363

Email: [email protected]

Instant Air Solutions

This software collects data from different sensors and controllers within the usual a/c system, integrating with products from numerous provider brand names. Our service provider after that provides the usual items information to us in an easy-to-understand layout, such as charts or graphes. For instance, a huge workplace building might discover that its power use, an usual issue across numerous product or services, spikes every weekday at noontime when the carrier systems are typically at peak procedure.

Commercial Air Filtration Systems Burbank, CACommercial Hvac Systems Burbank, CA

Commercial Hvac Services Burbank, CA

Emergency Hvac Repair Burbank, CA

Ductwork Cleaning Burbank, CA

Close By Seo Optimization Burbank, CA

Around Me Seo Marketing Company Burbank, CA

Furnace Installation Burbank, CA

Instant Air Solutions

Table of Contents

- – Furnace Installation Burbank, CA

- – Instant Air Solutions

- – Commercial Air Conditioning Service Burbank, CA

- – Commercial Hvac Burbank, CA

- – Furnace Services Burbank, CA

- – Heating Contractor Burbank, CA

- – Commercial Hvac Service Near Me Burbank, CA

- – Ductwork Cleaning Burbank, CA

- – Air Conditioning And Heating Company Burbank...

- – Ductwork Cleaning Burbank, CA

- – Commercial Hvac Installation Burbank, CA

- – Commercial Air Conditioning Service Burbank, CA

- – Commercial Air Conditioning Service Burbank, CA

- – Commercial Hvac Burbank, CA

- – Commercial Air Conditioning Service Burbank, CA

- – Instant Air Solutions

Latest Posts

Evaporative Cooler Replacement Van Nuys

Hood Filter Replacement La Canada Flintridge

Sierra Madre Restaurant Hood Cleaning Near Me

More

Latest Posts

Evaporative Cooler Replacement Van Nuys

Hood Filter Replacement La Canada Flintridge

Sierra Madre Restaurant Hood Cleaning Near Me