All Categories

Featured

Table of Contents

- – Best Rv Repair Near Me Norco, CA

- – OCRV Center

- – Motorhome Service And Repair Near Me Norco, CA

- – Rv Service Repair Near Me Norco, CA

- – Motorhome Repair Near Me Norco, CA

- – Motorhome Refrigerator Repair Norco, CA

- – Rv Generator Repair Norco, CA

- – Rv Repair And Service Near Me Norco, CA

- – Rv Repair Services Near Me Norco, CA

- – Camper Ac Repair Near Me Norco, CA

- – Rv Repair Centers Near Me Norco, CA

- – Rv Service Repair Near Me Norco, CA

- – Rv Solar Panel Installation Norco, CA

- – Rv Solar Panel Installation Norco, CA

- – OCRV Center

Best Rv Repair Near Me Norco, CA

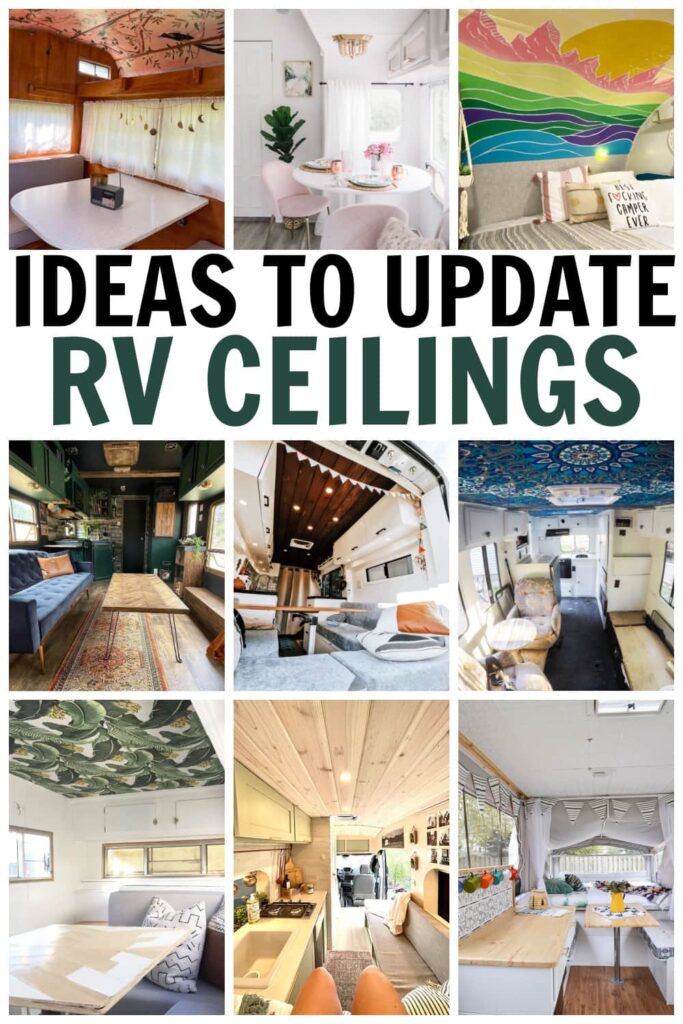

Epoxy was poured right into mold and mildews on the ground prior to being set up on the ceiling. The remainder of the ceiling was painted "Iron Ore" in shade and LED rope lights and light timber trim were added.

You can also produce hollow beam of lights by beating up and tarnishing 1x8s and afterwards framing them with each other, as one renovator suggested. Image Debt: Kento Eyre In this RV renovated by the pros at Wayland Ventures, straightforward discolored 2x6s produce beam of lights that run throughout the ceiling. Photo Credit Rating: Wayland Ventures This motor home is really an traditional bus in New Zealand!.?.!! To cover up the normally curved roof of the bus, proprietor Andy mounted timber paneling across portions of his recreational vehicle ceiling.

Picture Credit Score Terri Closs Right Here is what the owner, Terri, had to state concerning this ceiling! "Tin ceilings are infamously heavy.

Motorhome Service And Repair Near Me Norco, CA

"That ceiling floor tile was framed by timber molding down the length of the trailer with a versatile material molding following the curve of the ceiling. Just how do you hold these ceiling tiles in place while the adhesive dries out?

For an additional basic ceiling restoration, think about including aspects like a ceiling fan or a gorgeous lighting fixture. This can include both charm and feature to your ceiling. Image Credit: kevinodonnell143 You can use any kind of household lighting fixture in a RV as long as it is effectively installed.

Image Credit Rating: Camp Resurgence Would you restore your recreational vehicle ceiling? Go down a comment and share which of these designs is your favorite! Alyssa Padgett is the author of the very successful book, A Beginner's Guide to Staying in a RV. She enjoys all things #RVlife and travels full-time around the world with her household of 4.

Rv Service Repair Near Me Norco, CA

But still that will offer all the rainfall security I require to maintain the roof covering completely dry. Plus I'll still get good light and air flow and room to relocate ladders and materials around. Right here is my recreational vehicle canopy with the sidewall unit set set up. Prepared for rain! You'll notice the sidewalls are white while my original cover is tan.

This keeps water flowing off in reverse while driving, rather of having the tendency to blow under any type of joints. Yet the most important finding was that the. This produces a lamination effect (like adhesive in between layers of plywood) that develops a single stiff framework. It is considering how slim the plywood gets on both sides! Prior to I started taking apart the roofing system I can jump around on it and feel no flex.

This implies that in order to maintain a strong and lightweight roof,. Maybe your Motor home is made with wood 24 roof covering framing rafters and has thicker plywood decking on top.

Motorhome Repair Near Me Norco, CA

Now that I can see how the roof covering of the Motor home is constructed and the level of the water damages, I have some important decisions to make regarding exactly how to continue with my Recreational vehicle renovation. It's time to make a game plan for my Motor home remodel!

Yet yet And ultimately, I have to figure out the, so I do not fix something and after that have to undo it later on for the next repair service. Makeover projects resemble a video game of chess; you need to expect ten moves in advance to avoid screwing yourself along the method.

I can tell since the grooves reduced right into the styrofoam for electrical wiring are at the top of the foam and would certainly have been difficult if the roof covering was already on. So if I change the roofing system initially and afterwards desire to alter some electrical wiring in the ceiling later, just how would I obtain to it? (I would most likely end up placing awful surface-mounted circuitry tracks in. Rv Repair Services Near Me Norco.) An additional sequence problem is whether to do the? I can see that the rounded fiberglass panel at the top of the more than head bunk location overlaps the roof covering outdoor decking and the rubber roof covering.

Motorhome Refrigerator Repair Norco, CA

This set appears like a crazy alternative to me and way extra work than needed, yet it is still a choice, specifically if the water damage in your recreational vehicle is more substantial than mine. This would certainly require, and perhaps (like the shower room wall and closet wall surfaces) but leaving all the steel roof mounting in location.

Then put new layer of EPDM rubber roof on the top. This would most very closely re-create the original top quality of the manufacture, would be the lightest possible repair service and the strongest roofing lamination. A significant amount of job, taking apart cupboards and interior walls, as well as a great deal of removing circuitry and components.

PUT A COSMETIC LAYER OVER CEILING, SECOND LAYER OF ROOF COVERING PLY. This would certainly be the most convenient alternative, simply cut pieces of thin paneling to cover the entire ceiling (without getting rid of cabinets or walls).

Least expensive, most convenient, fastest. Will look equally as wonderful inside as in fact replacing all the ceiling ply Much heavier due to the fact that includes several layers of ceiling paneling and roof covering paneling. Less toughness since there will still be some peeled areas of ceiling and roofing outdoor decking. Worst of all, I 'd be capturing in rotten timber in the ceiling that might be expanding mold and mildew.

Rv Generator Repair Norco, CA

I think someplace in between these two extremes might be my best option. I can change all the 1/8 roof paneling with complete sheets and glue it along with possible for a complete stamina roofing, followed by brand-new EPDM roof. For the interior ceiling I would meticulously reduce out areas of the ceiling plywood that had water damages and came unglued from the foam insulation, and change them with meticulously matched items of the exact same density 1/8 luan plywood, and glue them to the foam as finest I can.

After that, because there would certainly be a useful yet crappy-looking hodgepodge of ceiling paneling in position, I would place a slim cosmetic layer of paneling over the ceiling between the cabinets in the living location. I might pick an eye-catching aged-wood or bead-board paneling that would certainly look adorable. I might either glue it as much as enhance lamination strength, or make use of detachable fasteners in case I wish to place wiring or components inside the ceiling later on.

Rv Repair And Service Near Me Norco, CA

At least this will get me going. OK, let's return to it! Next I'm mosting likely to remove the damaged wood from the roof..

JimI can not imagine why there would certainly be wrinkles on the ceiling. I assumed the ceiling panels were like paneling with a glued on coating on one side. Seeing creases I might only assume of a dripping roof somewhere.

Rv Repair Services Near Me Norco, CA

Please note: This article may have associate links, definition, if you click through and buy we (or those included in this article) might make a payment at no extra price to you. View our full-disclosure here. Among the greatest projects we took on last month was installing the brand-new ceiling panel in the motor home.

As you may know, a couple of months after we bought our motor home in 2015, we found a water leakage can be found in through the skylight. This really freaked us out because while we were intending to refurbish our motorhome, we had not intended on dealing with such a difficult task. We're just pleased we discovered it before we began any kind of large tasks.

Camper Ac Repair Near Me Norco, CA

You can find out more regarding that right here. We had actually spent a fair bit of time tidying up the damages, re-caulking every little thing to avoid future water problems, and setting up the new skylight. Nonetheless, the massive ceiling panel we had to have supplied on a products truck just sat in our garage for months daunting us every single time we walked past it.

Fun things. There was whole lots of determining, after that re-measuring, after that re-measuring again before cuts were made, and there might have been a number of vouch words also Abraham of The Walking Dead would certainly take pride in. Obviously, we are extremely stoked to ultimately have it up, woo-hoo! Eric was a champ and did most of the hard work so I'll let him discuss just how we replaced our ceiling panel.

We are not professionals and changed our ceiling panel to the most effective of our capacity with the assistance of our maker. Just like any kind of motor home task we recommend you talk to your supplier for ideal methods, in this manner you will certainly at the really least get information directly from the steed's mouth so to talk.

Keeping that claimed we really hope the information below is valuable for you and your project. You can watch our short video clip listed below: Once we realized we had water can be found in through our bathroom skylight we instantly put a tarp over the roof covering and called Tiffin, our motor home supplier. They were really practical in walking us with exactly how we could go around replacing the panel, however there is just a lot you can do over the phone.

Rv Repair Centers Near Me Norco, CA

Leave all of the walls and furniture in area and cut the new ceiling panel right into various pieces, after that put them in location. Take out all of the walls and closets then place the brand-new ceiling panel in place as a whole sheet.

I had not been a big fan of cutting the panel into lots of items and fitting them around the walls that remained in place. I could not persuade myself it was the very best alternative, it might have very well been the easiest, but I really felt either of the various other choices would certainly be extra secure.

Rv Service Repair Near Me Norco, CA

As we stood back and looked we decided it was going to be best to eliminate the wall surfaces and completely change the panel in its whole. When we showed up at the main kitchen area wall (the wall still up in the image above) we struck a couple of grabs, namely the water heater, and heating system were both set up against the wall surface in the reduced kitchen area cabinets.

When considering our ceiling with the old panel eliminated we recognized we had two walls that might essentially cover both the cuts we would need to make. One wall surface being the primary kitchen wall surface, the various other being the hallway/bathroom wall surface. Side-Note: We understood we would not be removing the cooking area wall surface, nevertheless, we believed we might be able to slide the new panel (still unscathed) over the wall surface while it was still in area.

We decided to make both cuts. I proceeded and gauged the range from the side of the panel to the center of the kitchen wall surface (insuring the cut would be hidden under the wall). I likewise chose to do this due to the fact that the wall would aid serve as a support for the 2 items of paneling we would certainly have after the cuts.

The same reasoning behind this cut as the other, to make certain when the hallway wall surface was returned in location it would line up straight with the cut we made in the ceiling panel. (in the above image you can see that the panel goes underneath the kitchen area wall, developing support while additionally concealing the cut we made) So currently we have two pieces of the paneling and we know where they are going to go, however what regarding the vents, skylight opening, and cables that require to come through the ceiling panel? It is best to obtain those areas measured and pre-drilled before you place the panel up.

Rv Solar Panel Installation Norco, CA

As opposed to disconnecting the cables, I made a simple cut with my round saw to the pre-drilled hole to make sure that I could move the wires into place. You might want to separate the cords initially, which would certainly be flawlessly fine, I would state use your finest judgment and do what appears right to you.

I did this to ensure that I might place the panel up and make sure my marks were appropriate with the idea that if they were incorrect I could after that make use of the right size little bit and appropriate somehow if required. Good luck was on my side and all the measurements were correct.

For the air vent covers and skylight openings, I made use of a drill bit large enough to allow my JigSaw blade in. I opted to obtain the panel in position and safeguarded prior to eliminating the larger openings, I did this due to the fact that I didn't intend to pre-cut after that pertain to learn it had not been aligned appropriately.

Rv Solar Panel Installation Norco, CA

Prior to we placed the adhesive on and positioned the panels we really required to reduce a very small of the edges off. When we had that completed the panels moved up into position, and we understood they would fit. We took our spray adhesive and covered both the ceiling and wood support of the panel, gave it a min to come to be tacky then pressed the two assemble.

Rv Repair Centers Near Me Norco, CACamper Ac Repair Near Me Norco, CA

Rv Mechanics Near Me Norco, CA

Rv Solar Installation Norco, CA

Motorhome Refrigerator Repair Norco, CA

Rv Delamination Repair Near Me Norco, CA

Full Service Rv Repair Near Me Norco, CA

Motorhome Generator Repair Near Me Norco, CA

Motorhome Repair Shop Norco, CA

Rv Floor Repair Near Me Norco, CA

Motorhome Repair Shops Norco, CA

Rv Plumbing Repair Near Me Norco, CA

Rv Refrigerator Repair Near Me Norco, CA

Rv Solar Installation Norco, CA

Rv Mechanics Near Me Norco, CA

Rv Repair Places Near Me Norco, CA

Motorhome Awning Repair Norco, CA

Rv Plumbing Repair Near Me Norco, CA

Motorhome Refrigerator Repair Norco, CA

Motorhome Repair Shop Norco, CA

Rv Ceiling Repair Norco, CA

Camper Ac Repair Near Me Norco, CA

Rv Repairs Near Me Norco, CA

Rv Plumbing Repair Near Me Norco, CA

Rv Generator Repair Norco, CA

Rv Solar Installation Norco, CA

Rv Repair Service Near Me Norco, CA

Motorhome Repair Service Norco, CA

Motorhome Generator Repair Near Me Norco, CA

Rv Repair Shops Near My Location Norco, CA

Rv Solar Installation Norco, CA

Rv Repair Services Near Me Norco, CA

Rv Repair Shops Near My Location Norco, CA

Motorhome Generator Repair Near Me Norco, CA

Motorhome Repair Near Me Norco, CA

Motorhome Refrigerator Repair Norco, CA

Motorhome Refrigerator Repair Norco, CA

Camper Ac Repair Near Me Norco, CA

Camper Ac Repair Near Me Norco, CA

Rv Solar Panel Installation Norco, CA

Rv Repair Places Near Me Norco, CA

Best Rv Repair Near Me Norco, CA

Motorhome Awning Repair Norco, CA

Rv Repair Services Near Me Norco, CA

Rv Repairs Near Me Norco, CA

Rv Mechanics Near Me Norco, CA

Rv Repairs Near Me Norco, CA

Rv Mechanics Near Me Norco, CA

Motorhome Repair Near Me Norco, CA

Motorhome Refrigerator Repair Norco, CA

Rv Mechanics Near Me Norco, CA

Rv Generator Repair Norco, CA

Rv Plumbing Repair Near Me Norco, CA

Rv Repair In My Area Norco, CA

Rv Repair Shops Near My Location Norco, CA

Rv Repair Places Near Me Norco, CA

Rv Solar Installation Norco, CA

Full Service Rv Repair Near Me Norco, CA

Motorhome Service And Repair Near Me Norco, CA

Rv Solar Panel Installation Norco, CA

Motorhome Refrigerator Repair Norco, CA

Rv Repair Shops Near My Location Norco, CA

Rv Service Repair Near Me Norco, CA

Rv Mechanics Near Me Norco, CA

Rv Repair Centers Near Me Norco, CA

Rv Plumbing Repair Near Me Norco, CA

Motorhome Service And Repair Near Me Norco, CA

Rv Repair Service Near Me Norco, CA

Rv Repair Services Near Me Norco, CA

Rv Floor Repair Near Me Norco, CA

Rv Repairs Near Me Norco, CA

Rv Service And Repair Near Me Norco, CA

Rv Solar Installation Norco, CA

Motorhome Generator Repair Near Me Norco, CA

Rv Mechanics Near Me Norco, CA

Rv Generator Repair Norco, CA

Rv Service Repair Near Me Norco, CA

Rv Repair In My Area Norco, CA

In My Area Seo Services Pricing Norco, CA

Finding A Good Seo Management Norco, CA

OCRV Center

Table of Contents

- – Best Rv Repair Near Me Norco, CA

- – OCRV Center

- – Motorhome Service And Repair Near Me Norco, CA

- – Rv Service Repair Near Me Norco, CA

- – Motorhome Repair Near Me Norco, CA

- – Motorhome Refrigerator Repair Norco, CA

- – Rv Generator Repair Norco, CA

- – Rv Repair And Service Near Me Norco, CA

- – Rv Repair Services Near Me Norco, CA

- – Camper Ac Repair Near Me Norco, CA

- – Rv Repair Centers Near Me Norco, CA

- – Rv Service Repair Near Me Norco, CA

- – Rv Solar Panel Installation Norco, CA

- – Rv Solar Panel Installation Norco, CA

- – OCRV Center

Latest Posts

Ac Troubleshooting Pacoima

Swamp Cooler Copper Line Repair Monterey Park

North Hollywood Swamp Cooler Motor Repair

More

Latest Posts

Ac Troubleshooting Pacoima

Swamp Cooler Copper Line Repair Monterey Park

North Hollywood Swamp Cooler Motor Repair