All Categories

Featured

Table of Contents

- – Kitchen Exhaust Cleaning Service Tujunga, CA

- – Instant Air Solutions

- – Commercial Hood Installation Tujunga, CA

- – Professional Hood And Duct Cleaning Tujunga, CA

- – Kitchen Hood Maintenance Tujunga, CA

- – Hood Filter Replacement Tujunga, CA

- – Kitchen Hood Service Tujunga, CA

- – Kitchen Hood Service Tujunga, CA

- – Kitchen Exhaust Cleaning Service Tujunga, CA

- – Restaurant Hood Cleaning Service Tujunga, CA

- – Hood Filter Cleaning Tujunga, CA

- – Fire Suppression System Inspection Tujunga, CA

- – Kitchen Hood Repair Service Tujunga, CA

- – Kitchen Hood Inspection Tujunga, CA

- – Commercial Hood Installation Tujunga, CA

- – Instant Air Solutions

Kitchen Exhaust Cleaning Service Tujunga, CA

Exhaust hoods can be classified based on their applications and installation configurations. At NFP, we use high-grade array hoods for any application and setup.

They're usually equipped with a fire reductions system. Their makeup air systems regularly bring fresh air in to replace the tired air and keep stress balance. These hoods can not handle grease, so they're installed over ovens, cleaners, and any other non-grease-producing appliances. Kind II hoods remove warmth, steam, and odors from the air and supply a much more comfortable environment.

Commercial Hood Installation Tujunga, CA

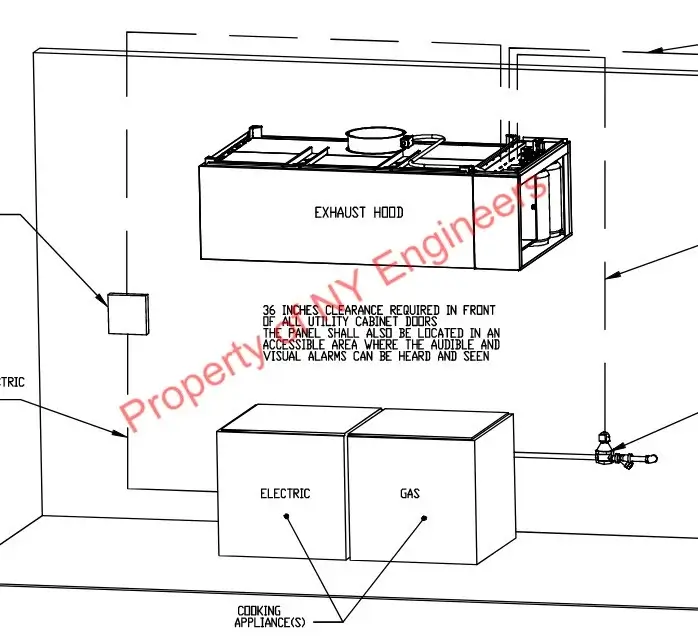

In industrial kitchens, it's common that some cooking home appliances are put in the facility of the cooking area, not versus a wall. Hoods (type I, II, and ventless) are suspended from the ceiling right over the food preparation equipment to offer efficient coverage. Proper setup and taking into consideration good structural support are important to make sure the hood is securely connected and can be made use of without any type of issue

They're put closer to the surface area of the food preparation devices for a more efficient exhaust of grease vapors and damaging fumes. They often tend to take less space and this has actually made them a fantastic choice for locations with limited space, such as food trucks.

Business cooking areas in hotels, dining establishments and various other friendliness markets are constantly active - Tujunga Commercial Kitchen Hood Service. Employees in these cooking areas usually spend extra shifts. Long working hours can lead to a build-up of smoke and warmth. Due to this buildup, the majority of restaurant cooking areas mount a kitchen area hood. Alturas contractors help you do just that, with a group of hood installers in Los Angeles.

Professional Hood And Duct Cleaning Tujunga, CA

Right here are a few of the indicate think about prior to you speak to a handyman for hood installment. If you are a new dining establishment owner, and seeking industrial hood setup business near you in Los Angeles, this list will assist you discover the best one. See to it to employ licensed service technicians that recognize restaurant air flow systems.

Hire someone that already has experience with the top industrial hood brands that you are considering. Security is one of the important elements to consider for Cooking area air flow.

To prevent grease fires, Kind 1 kitchen area hoods should be cleansed routinely. The condensate hoods are additionally recognized as Type 2 Commercial kitchen area Hoods.

Kitchen Hood Maintenance Tujunga, CA

Condensate hoods do not include a grease filter and are generally manufactured from galvanized ducts as opposed to welded. The exhaust air flow and how it's taken care of are crucial considerations. Setup prices for a ductless system are lower than for an aired vent exhaust-style system with ductwork, depending upon the exhaust air flow system you choose.

As a result, they're much less costly than a Type I hood with an exhaust system. A system like this needs to not be utilized in a cooking area that produces a great deal of oil.

Professional installment of air flow systems, consisting of cooking area hoods and business hoods, is essential to make sure appropriate air movement and security in commercial kitchens. The hood setup process includes careful planning and adherence to neighborhood codes, and it calls for experienced knowledge to install an industrial kitchen area air flow system properly.

We give a list of ventilation solutions in dining establishments, workplaces, grocery stores, and health centers. Feel complimentary to get in touch with us for industrial hood installment estimates.

Hood Filter Replacement Tujunga, CA

Installing a hood system in a restaurant on your own may not be the ideal idea. We suggest you call industrial hood installation companies to aid you.

With the aid of a professional kitchen hood installer or HVAC professional, setting up a kitchen hood for a restaurant should not take longer than 60 minutes. In some cases, depending upon the requirements in a business configuration, it might take longer. It is best to get in touch with a professional for an on-site price quote before air vent hood or range hood setup.

They must likewise consist of: Fire reductions systemsGrease filtersExhaust followers with ductwork These hoods are made use of for home appliances that emit heat or vapor however not oil, such as dishwashers and stoves. They lack fire suppression but require reliable air capture.

: These are the most common type of commercial kitchen area exhaust hoods, normally linked to the wall surface over the oven and vented outside. Constructed from stainless steel, they are resilient and customizable for any kind of kitchen layout.: Suspended from the ceiling above an island or freestanding cooktop, these hoods require more effective ventilation and often tend to be a lot more costly due to their architectural requirements.: The least usual in industrial setups, these are mounted under a closet or kitchen counter.

Kitchen Hood Service Tujunga, CA

When mounting a kitchen hood, it's critical to make use of corrosion-resistant ductwork that holds up against the greasy and damp kitchen area atmosphere. All electrical elements need to be GFCI-protected to enhance safety.

Prior to installment, it is very important to coordinate with the local fire marshal and building department. Prepare and submit a detailed MEP (Mechanical, Electrical, Pipes) strategy to help with a smooth permitting procedure and ensure local code conformity. To preserve optimal performance, tidy grease filters at the very least regular, or extra often depending on cooking volume.

Kitchen Hood Service Tujunga, CA

A is needed for home appliances that produce oil and smoke (e.g., fryers, grills, broilers). Always examine regional fire and building codes for details needs.

As a regulation of thumb, the hood needs to of the devices and supply adequate air flow for effective ventilation and code conformity. have to include a, designed particularly for grease fires. These systems must be properly based on standards.

All dining establishments, whether they are industrial chain dining establishments or any type of family-owned walk-in diners must implement actions to take care of air flow better. Industrial kitchen area air flow systems additionally recognized as restaurant hoods play an important duty in efficiently circulating the air within cooking areas. Their key objective is to successfully eliminate smoke and odours that are generated during the cooking process.

Kitchen Exhaust Cleaning Service Tujunga, CA

It can be challenging to establish the perfect location, mounting the ventilation hood, and attaching the ductwork. These business kitchen hoods are all essential parts of your business kitchen ventilation system.

There are 2 main factors why you would require to install a Restaurant hood. The first is to change an old dining establishment hood, and the 2nd is to part of a brand-new commercial restaurant hood system you are installing. Whatever your motivation for setting up a new restaurant hood, the extra prepared you are, the simpler your setup will be.

Restaurant Hood Cleaning Service Tujunga, CA

It is necessary to always think about hiring a registered contractor when repairing the Dining establishment Hood. In many cases, an inept installation might possibly void the warranty terms. After that, you need to place the dining establishment hood in an area large enough to lay air duct with few challenges and far from flammable products.

You have to consider using protective safety glasses, steel-toed shoes, gloves, and earmuffs to minimize the risk of any type of kind of injury. When you have gotten the completely protected Restaurant hood installation, it is necessary to unbox it with care. Make sure to stay clear of bending, damaging, or denting any kind of part of the hood throughout the unpacking procedure.

For that, inspect the nameplate specs and the billing for all various other components to ensure you received the ideal tools. If difficulties develop, speak to the producer. Before mounting, review the dining establishment hood layout for manufacturing facility designs. To place the dining establishment hood assembly according to the last layout, you can utilize the flooring.

These adjustments ought to be made by the specs given in the hood weight index, which can be found in the installation guidebook. Make use of a 1/2-inch threaded pole placed to the roof covering structural beam of lights for hanging the dining establishment hood. Make use of a power chauffeur to drill 9/16-inch holes right into the roof architectural beams, lining up with the air flow hood's angled installing brackets.

Hood Filter Cleaning Tujunga, CA

Set up a 1/2-inch threaded rod between placing braces on the ventilation hood and architectural light beams. Safeguard the pole using fender washers and nuts. Weld the exhaust duct to the air flow hood while it gets on the floor. Make certain a total weld to stop leaks, consisting of at the connection factor between the restaurant hood and exhaust collar.

Placement the 1/2-inch threaded rods regarding 1/2 inch closer to the back wall surface top hanger to straighten the ventilation hood flush versus the wall surface. Validate that the ventilation hood hangs level. Set up grease filters, grease mugs, and illumination into the ventilation hood. Apply stainless steel gloss to get rid of accumulated grit and gunk from the restaurant hood.

Handy for you: Total Restaurant Ventilation System Overview It is for certain that your industrial restaurant hood will certainly constantly include a whole collection of detailed guidelines from the manufacturer to allow you know how to mount a restaurant hood. While managing your fan, attempt not to lift it by the follower hood.

Attempt to handle it with treatment to stop damages to both your fan along with your roof. In instance you currently do not have actually one mounted, you will certainly require to set up a roof covering visual all from the ground up. Comply with the maker's standards and instructions for safeguarding the aesthetic to the roof.

Fire Suppression System Inspection Tujunga, CA

During the procedure of installation, you may first need to make certain that your power resource works with the needs of your business restaurant hood. Always attempt to make certain that you constantly separate the power supply prior to starting any type of service or near a restaurant hood. It would constantly be a great idea to safeguard the power line to prevent any unexpected contact with sharp items or devices.

This indicates that you might invest even more than the cost approximated over if you are considering a premium industrial variety hood for your cooking area. The quantity of food preparation you would prepare to do would also help to establish the devices you require to buy for your cooking area. You can constantly select to go with a general-purpose business array in situation you intend to do a great deal of food preparation and baking which can set you back anywhere between $1100 and $10,000.

Kitchen Hood Repair Service Tujunga, CA

To cleanse your kitchen air most efficiently, acquire a ducted range hood. In general, many installments require a range from 20 to 24 in between the bottom of the hood and the cooking surface.

Then, utilize a degreasing remedy to tidy surface areas, rinse thoroughly, and reinstall filters.

Kitchen Hood Inspection Tujunga, CA

When doubtful, seek advice from a business cooking area professional. A cooking area hood need to be mounted straight over the cooking devices, but the precise placement relies on the hood design and the devices under it. Your local code might specify a minimum and optimum height. As soon as you have actually chosen your industrial cooking area hood, you require to get it along with any type of essential setup equipment.

Begin by noting the area where the hood will be installed. Ensure the hood is flawlessly leveled. Use mounting braces to secure the hood to the wall or ceiling, relying on your layout. It's advised to have a professional or a person with strong do it yourself abilities do this. The ductwork links the hood to the exhaust follower.

Make sure the air ducts are installed to air vent the exhaust air exterior of the structure. The exhaust follower requires to be installed on the exterior wall surface or roof covering, and connected to the ductwork originating from the hood. Make certain it's installed effectively so that it properly gets rid of smoke, warmth, and smells.

Keep in mind, these are basic steps and might differ based on the specific sort of hood and neighborhood policies. Constantly speak with a professional if you're unclear. And always remember, security ought to constantly be the initial top priority. In the process of establishing up a commercial cooking area, you'll inevitably encounter the demand for a commercial-grade ventilation hood.

Commercial Hood Installation Tujunga, CA

Placing an industrial kitchen area hood is a job that shouldn't be tried without expert assistance. Here's what you require to comprehend concerning the installation process and why engaging a professional is essential. The journey towards installation should start with a consultation with a specialist hood maker. Experts in this field can direct you in picking the ideal hood for your cooking area, factoring in facets like your cooking area's size, your cooking design, and regional building codes and regulations.

Instant Air Solutions

Address: 412 W Dryden St Apt 6 Glendale, CA 91202Phone: (747) 307-6363

Email: [email protected]

Instant Air Solutions

Inadequate setup might cause air leakages, compromising the hood's effectiveness and potentially creating fire risks. By working together with knowledgeable specialists, you can ensure your hood is mounted to abide by industry requirements and finest methods. The business kitchen hood installment process involves numerous crucial actions. Initially, the installer mounts the hood to either the ceiling or wall.

Hood Filter Cleaning Tujunga, CAKitchen Hood Service Tujunga, CA

Kitchen Hood Grease Removal Tujunga, CA

Kitchen Exhaust Fan Repair Service Tujunga, CA

Commercial Kitchen Hood Cleaning Tujunga, CA

Professional Hood And Duct Cleaning Tujunga, CA

Kitchen Hood Grease Removal Tujunga, CA

Commercial Kitchen Hood Cleaning Tujunga, CA

Restaurant Hood Cleaning Near Me Tujunga, CA

Commercial Kitchen Ventilation Tujunga, CA

Fire Suppression System Inspection Tujunga, CA

Fire Suppression System Certification Tujunga, CA

Kitchen Hood Grease Removal Tujunga, CA

Kitchen Exhaust Cleaning Service Tujunga, CA

Kitchen Exhaust Installation Tujunga, CA

Commercial Kitchen Ventilation Tujunga, CA

Restaurant Ventilation Cleaning Tujunga, CA

Restaurant Hood Cleaning Near Me Tujunga, CA

Restaurant Kitchen Ventilation Tujunga, CA

Kitchen Exhaust Cleaning Service Tujunga, CA

Commercial Kitchen Hood Installation Tujunga, CA

Restaurant Hood Installation Tujunga, CA

Kitchen Hood Service Tujunga, CA

Commercial Kitchen Ventilation Tujunga, CA

Commercial Kitchen Hood Cleaning Tujunga, CA

Kitchen Hood Maintenance Tujunga, CA

Commercial Kitchen Hood Installation Tujunga, CA

Kitchen Hood Repair Near Me Tujunga, CA

Hood Filter Cleaning Tujunga, CA

Commercial Kitchen Ventilation Tujunga, CA

Commercial Hood Installation Tujunga, CA

Commercial Kitchen Ventilation Services Tujunga, CA

Kitchen Exhaust Cleaning Service Tujunga, CA

In My Area Seo Services For Business Tujunga, CA

Finding A Local Top Seo Company Tujunga, CA

Instant Air Solutions

Table of Contents

- – Kitchen Exhaust Cleaning Service Tujunga, CA

- – Instant Air Solutions

- – Commercial Hood Installation Tujunga, CA

- – Professional Hood And Duct Cleaning Tujunga, CA

- – Kitchen Hood Maintenance Tujunga, CA

- – Hood Filter Replacement Tujunga, CA

- – Kitchen Hood Service Tujunga, CA

- – Kitchen Hood Service Tujunga, CA

- – Kitchen Exhaust Cleaning Service Tujunga, CA

- – Restaurant Hood Cleaning Service Tujunga, CA

- – Hood Filter Cleaning Tujunga, CA

- – Fire Suppression System Inspection Tujunga, CA

- – Kitchen Hood Repair Service Tujunga, CA

- – Kitchen Hood Inspection Tujunga, CA

- – Commercial Hood Installation Tujunga, CA

- – Instant Air Solutions

Latest Posts

Water Heater Install North Clairemont

Tankless Hot Water Heater Installers Near Me Tierrasanta San Diego

Miramar Toilet Plumber Near Me

More

Latest Posts

Water Heater Install North Clairemont

Tankless Hot Water Heater Installers Near Me Tierrasanta San Diego

Miramar Toilet Plumber Near Me